The production of the heavy-duty grates proceeds according the same principle as that of the press-gratings. To produce our Heavy Duty Gratings we use high-quality band steel. The production is carried out on computer-controlled equipment. The desired dimensions can be like this precisely maintained.

The MKL heavy duty gratings are suitable for particularly heavy loads. In the production material is used from 4 mm thickness, which considerably increases the load capacity. Heavy-duty gratings are generally provided with a flat edging. This is just as thick as the supporting rods. For all types of both the supporting and the cross bars can be fitted with anti-slip properties. May also in the heavy duty grates are made in consultation with the technical management of production, special designs.

MKL provides you with galvanized or ungalvanized Press gratings made of steel (S235JR (St 37-2)), other materials such as stainless steel gratings from quality AISI 304 (1.4301) and AISI 316L (1.4404).

You will receive a competent and reliable technical advice.

Heavy Duty Gratings

MKL provides you with galvanized or non-galvanized press gratings made of steel (S235JR (St 37-2)), as well as other materials, such as stainless steel gratings with quality standard AISI 304 (1.4301) or AISI 316L (1.4404). in case of urgent needs and if orders are done in the framework of our special MKL-SPEED-PROGRAM, we will deliver the press gratings within the exceptionally short delay of 48 hours.

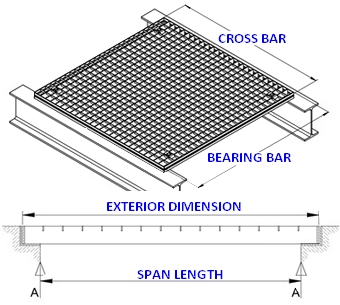

Manufacturing length

Bearingbar: max. 3000 mm

Crossbar: max. 1500 mm

Grating sizes

Standard maximal 2 m²

Special sizes in consultation

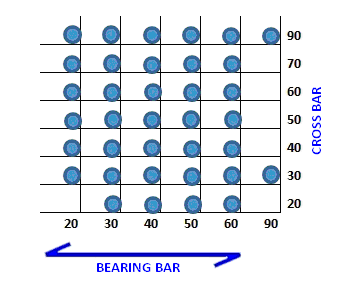

Meshes

Materials

MKLused a flat steel with profiling to bordering the gratings. Other border as T-profile or flat steel. Those can be ordered on request. When MKL-SPEED-PROGRAM T-profile is used exclusively.

When need slip resistance there are different versions. The anti-slip combination of bearing and cross-bars have an influence on the corresponding class (R10-R13).

| CSM2 type | Serrated bearing-bars + serrated cross-bars; |

|---|---|

| CSM2-1 type | Serrated bearing-bars; |

| CSM2-2 type | Serrated cross-bars. |

Important!