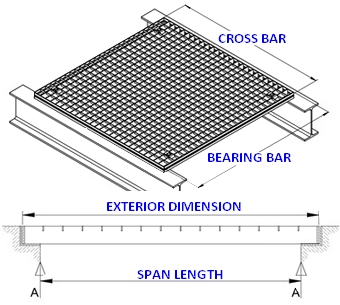

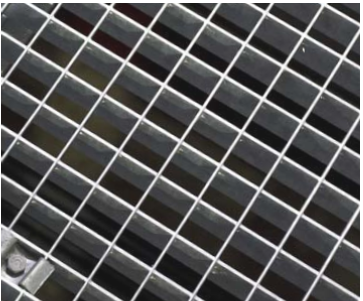

To produce the MKL press gratings we use high-quality band steel. The production is carried out on computer-controlled equipment, so the desired dimensions can be perfectly maintained. A grid of bearing- and crossbars makes up the basic structure. The crossbars are pressed into the previously cut-out bearing bars and a bordering is added to the grid. Thanks to the high torsional rigidity and stability, our press-gratings have the strength to carry quite heavy loads.

As versatile components with a good price-performance ratio, the press-gratings could be used practically anywhere:

• walk/gang ways

• machine and service platforms

• crane and work platforms

• heavy-duty gratings

• floor coverings

• cable channels

• cladding / panels

• facade gratings

• stairways and landings

• shelving

• ventilation gratings

• sun protection elements

Press gratings

MKL provides you with galvanized or non-galvanized press gratings made of steel (S235JR (St 37-2)), as well as other materials, such as stainless steel gratings with quality standard AISI 304 (1.4301) or AISI 316L (1.4404). In case of urgent needs and if orders are done in the framework of our special MKL-SPEED-PROGRAM, we will deliver the press gratings within the exceptionally short delay of 48 hours.

Manufacturing length

Bearing bar: max. 6000 mm

Cross bar: max. 2000 mm

Grating sizes

Standard maximal 2 m²

Special sizes can be obtained after consultation

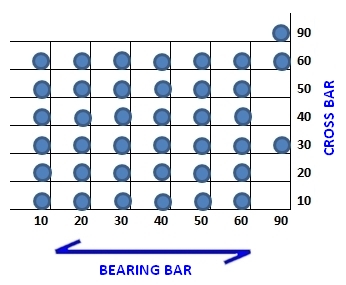

Meshes

Materials

MKL makes use of flat steel with profiling or flat steel for bordering of gratings. Special T-profile border can be ordered on your request and will indeed be the sole option if you’re making orders using our MKL-SPEED-PROGRAM.

Surface treatment

- Pickled

- Untreated

- Powder coating (according to RAL)

- Anodising (according anodizing panel)

In case of special needs regarding slip resistance, there is a choice between different anti-slip versions. The combination of anti-slip characteristics of bearing bars and cross-bars will together tdefine the final quality class (R10-R13).

| CSM2 type | Serrated bearing-bars + serrated cross-bars |

|---|---|

| CSM2-1 type | Serrated bearing-bars; |

| CSM2-2 type | Serrated cross-bars. |

Important!