The MKL-INOX gratings are manufactured in different steel grades. The production process differs from the production of the press-gratings only in the use of stainless steel. Stainless steel grids are mostly used in the food industry (breweries, commercial kitchens), sewage treatment plants or nearby seawater. MKL stainless steel gratings are also common as design options in facades and entrance areas. As versatile components with a good price-performance ratio, they are used practically everywhere:

• Running- and control bridges

• Heavy-duty gratings

• Floor coverings

• Light shaft covers

• Privacy screens

• Façade gratings

• Steps and podiums

• Ventilation gratings

Inox / Stainless Steel Grating

Because of the composition of the raw material, MKL-INOX gratings are resistant to weakly or even highly concentrated acids and alkalis. Accurate knowledge of the stress conditions is important to determine the right material.

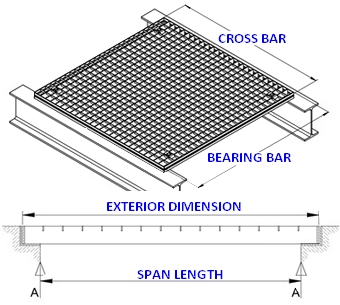

Bearing-bars

20×2 – 25×2 – 30×2 – 35×2

40×2 – 45×2 – 50×2 – 60×2

20×3 – 25×3 – 30×3 – 35×3

40×3 – 45×3 – 50×3 – 60×3

20×5 – 25×5 – 30×5 – 35×5

40×5 – 45×5 – 50×5 – 60×5

Special manufacturing measures: height 20mm only on request.

Manufacturing length

Bearing bars: max. 2500 mm

Crossbar: max. 2500 mm

Grating sizes

Standard maximal 2 m²

Meshes

Materials

1.4301 (V2A) 1.4571 (V4A)

MKL makes use flat steel for bordering of gratings.

Surface treatment

Stained

Untreated

Electrochemically polished

Glass bead blasted

Powder coating (according to RAL)

Antislip version

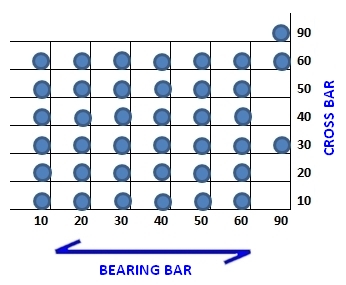

In case of special needs regarding slip resistance, there is a choice between different anti-slip versions. The combination of anti-slip characteristics of bearing and cross-bars will together define the final quality class (R10-R13).

| CSM2 type | Serrated bearing-bars + serrated cross-bars; |

|---|---|

| CSM2-1 type | Serrated bearing-bars; |

| CSM2-2 type | Serrated cross-bars. |

Important